Products

Back Pans

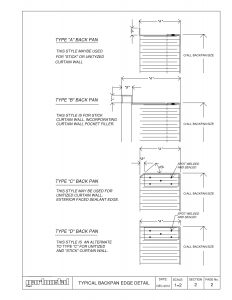

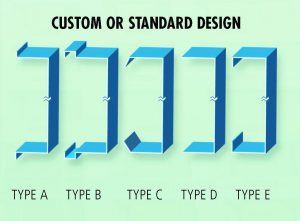

These are generally used in curtain wall systems, either behind a metal panel or on the back of spandrel glass. They provide excellent insulation, fire safety and sound absorption capabilities. Yarlmetal produces back pans of various shapes and sizes; the most common ones are rectangular bases with straight clips. Special adapters are formed at the end of the clip to suit the installation.

Each adapter is utilized for specific needs and requirements. For more information, please contact the sales department The above items refer to the different variables that are taken into consideration in designing backpans and they can be adapted in various ways to produce customized back pans to fit every space and requirement.

What we can Do?

The following variables are taken into account in determining the profile of the backpans

- The sectional depths of the curtain wall and window influence the pan depth.

- Most common insulation has "R" value 4/ inch Thickness of insulation will vary depending on the R factor, type of insulation and pan depth.

- The profile of the back pan depends on how the glass is installed.

- The back pan material is selected based on the finish specifications.

- Width and height of the pan are in most cases ¼ inches less DLO (Day Light Opening).